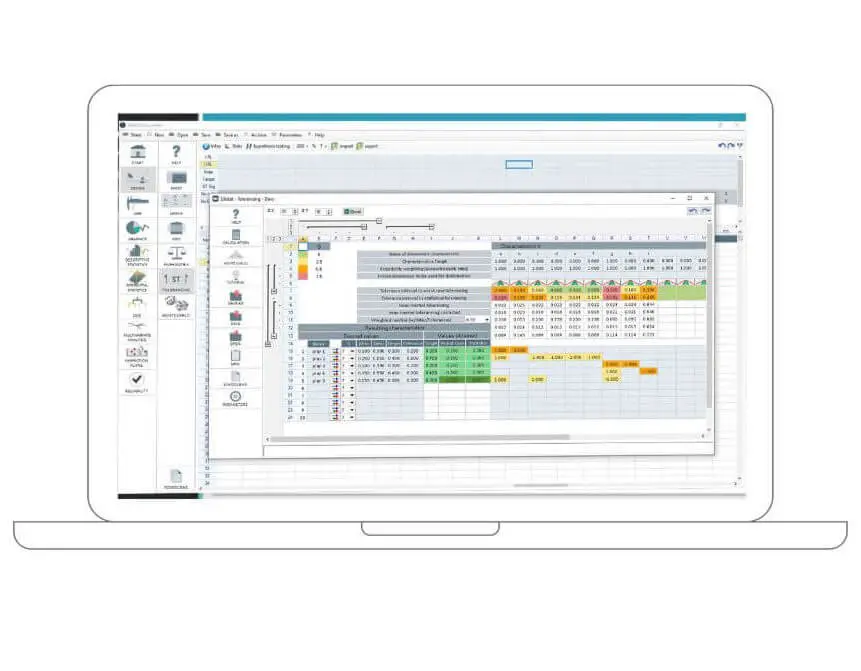

Optimize dimensions and tolerances with CAT

Tolerancing Stack Up Simulation Software

The Module for Tolerancing in Industry 4.0

To innovate is to go beyond simply digitalizing the existing

Test under real conditions

Tolerancing via Monte Carlo

Ellistat automatically performs all tolerance calculations under all assumptions. You can optimize with constraints. For example, one of the dimensions may have to be twice as wide as the others.

Ellistat can also simulate non-linear dimension chains

All types of tolerancing

Worst case, Quadratic statistic, Inertial statistic, Corrected inertial statistic, Weighted inertial statistic

A complete solution for Industry 4.0

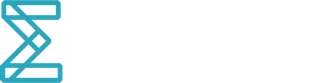

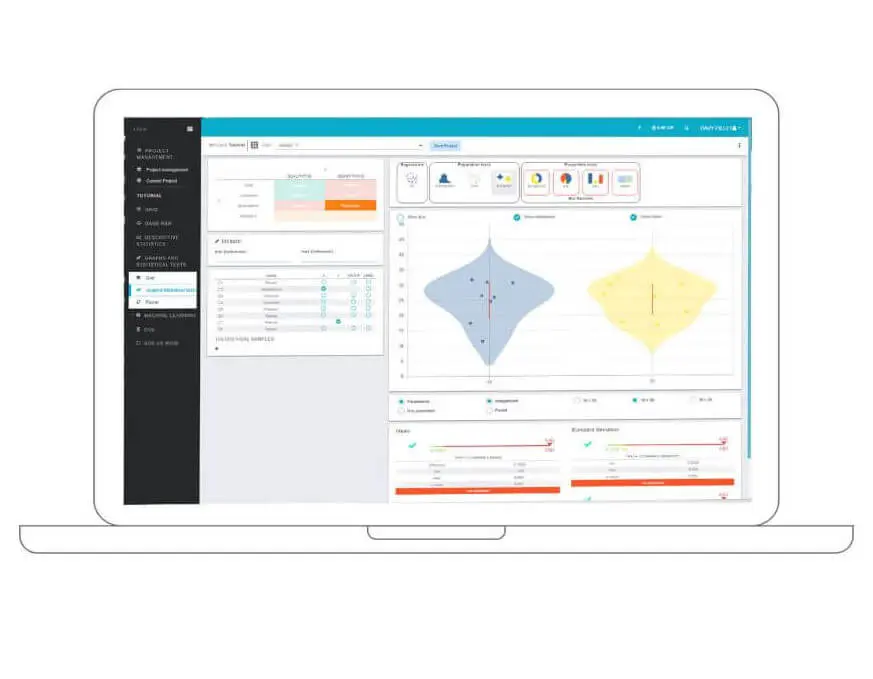

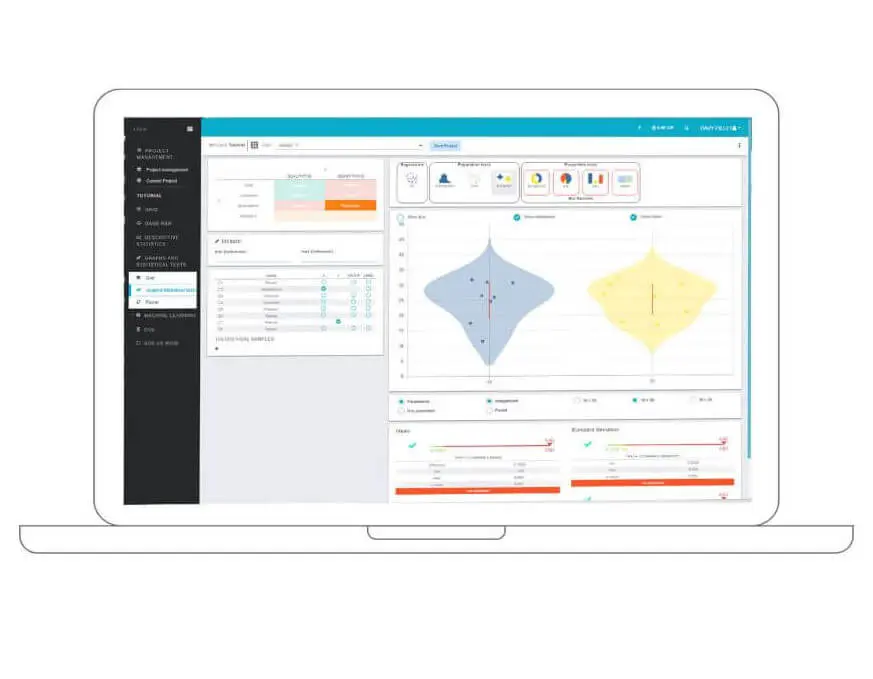

MSP / SPC

Statistical analysis

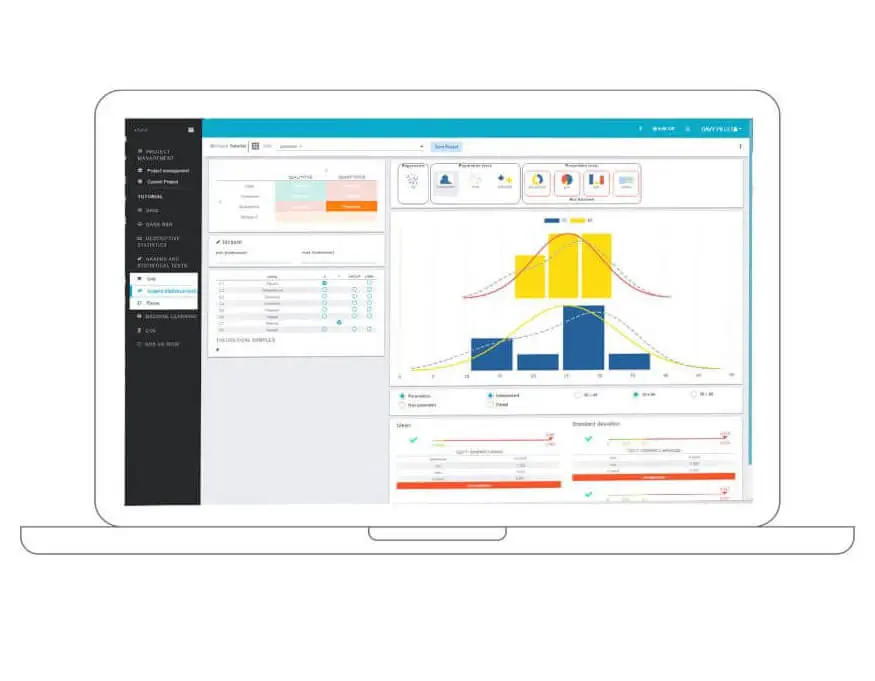

Experimental design

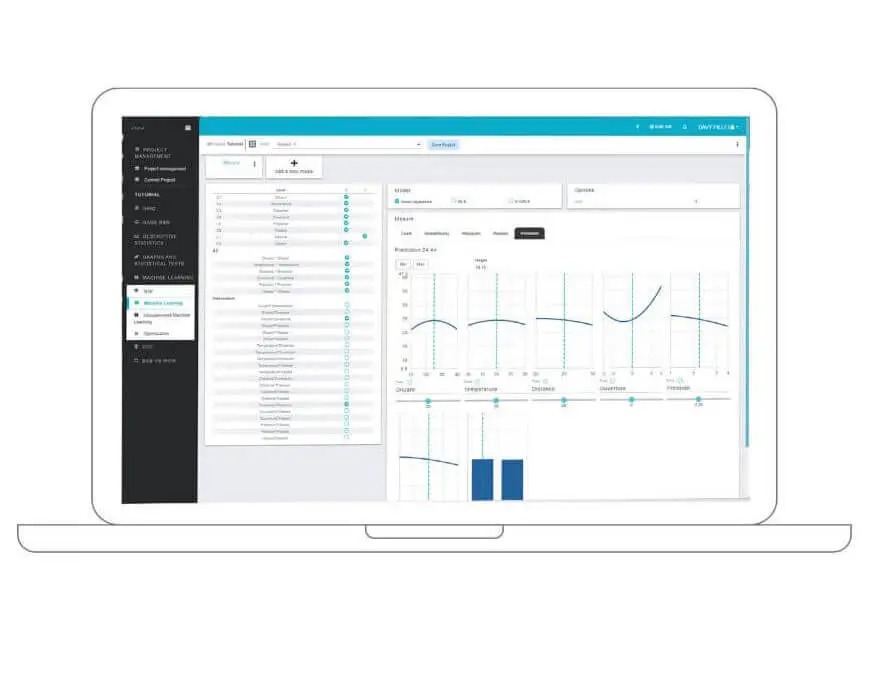

Machine learning

Graphical analysis

Format your data

MSA

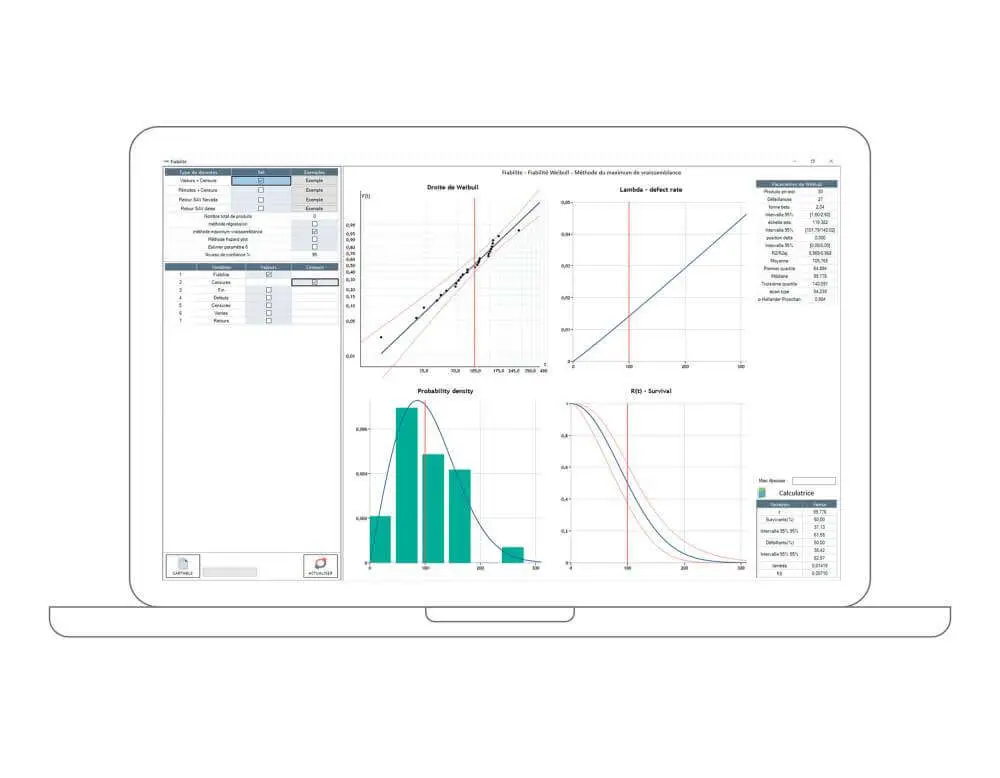

Reliability

Conception

Your feedback

Ellistat, an intuitive statistical tool

As part of the continuous improvement of our product offering, both in the development and production phases, I wanted to develop a number of quality tools within the WIRQUIN Group. To achieve this, and given the stakes involved, it quickly became apparent that a data processing software package was essential to increase efficiency. I quickly chose Ellistat because of its numerous on-board functions and its easy access, even if the algorithms behind it are not so easy! What's more, its floating, rather than individual, licensing principle means a rapid return on investment. Don't ask me how we'd do without Ellistat now - I can't answer that question!

Complete, powerful, efficient and impressively simple! A must-have for anyone who needs to have their data talked about.

A price to suit your needs

Trial

0€

Data Analysis module

- 30 days

- All Ellistat functions

- 1 User

Technical support and updates included

Student / Teacher

0€

Data Analysis module

- 1 year

- All Ellistat functions

- 1 User

- Dedicated license for students with a student card currently valid

Technical support and updates included

Standard

79/user/month

Data Analysis module

- License renewed every month

- All Ellistat functions

- Unlimited users

- Technical support and updates included