Ellistat unveils ELLICAM, a module that simplifies machine-tool autonomy and guarantees compliant parts right from the first production run. It will be presented at the Global Industrie of Lyon.

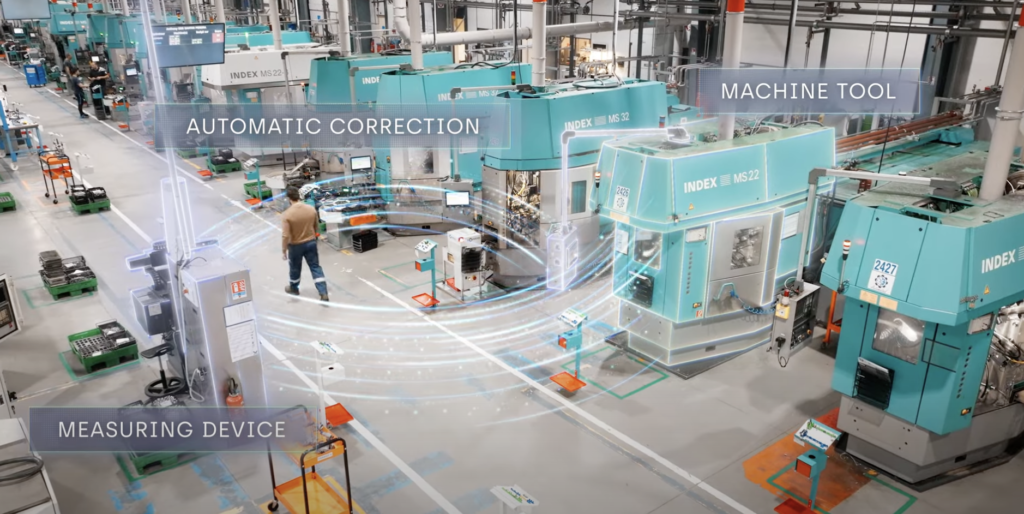

Ellistat announces the creation of a new module to its software solution APC (Automated Process Control), which enables machine tools to "operate autonomously, without human intervention, while guaranteeing 100% of good parts", assures the Haute-Savoie-based publisher. Presented at the forthcoming Global Industrie trade show, from March 11 to 14 at Eurexpo Lyon 2025, the ELLICAM module integrates machining data from the CAM software used in the company to configure the APC closed loop. Ellistat's technology then collects the measurement data, automatically calculates corrections and sends them directly to the machine tool, whatever its numerical control.

The IT company, founded in 2017, explains that ELLICAM directly links part design information (3D + machining program) to APC software, which corrects the machine tool in real time. And it points out that it is no longer necessary to specifically configure toolpaths in the APC, since the software will directly retrieve this information from the CAM software.

"It's a revolution

It's a revolution that will enable our customers and all industrial machinists to deploy APC on all their machines, even for small production runs," comments Ellistat CEO Davy Pillet. Indeed, the main obstacle to the massive automation of machine tools remains the time it takes to configure a new part. When a workshop has to produce more than 2000 part numbers per year, operators don't have the time to adapt the APC software to all the parts produced. This is now a thing of the past, as ELLICAM eliminates around 80 % of configuration time for each new part number.

But how does it work in the workshop?

From a plug-in dedicated to the CAM software used, all you have to do is press a button to automatically export the 3D of the part, along with the information needed to configure the APC," says Ellistat.

Data is transmitted via the network, and no prior knowledge of APC is required, assures this specialist in software for the mechanical engineering industry. Although, at the time of writing, only the plugin for AlphaCAM is available, Ellistat indicates that other plugins are under development, citing TopSolid, GibbsCAM and Esprit, among others. The aim is to cover most of the CAM solutions available.

"With recent developments to our flagship APC solution, the closed loop is finally complete. At the touch of a button, we can start producing 100% compliant parts as soon as the first part is machined", says Davy Pillet with satisfaction. We are now working on interoperability with all CAM software on the market to meet the needs of all manufacturers, and will continue our developments to anticipate the future technological needs of the precision engineering industry."