Method, prerequisites and best practices for successfully implementing APC in your workshop

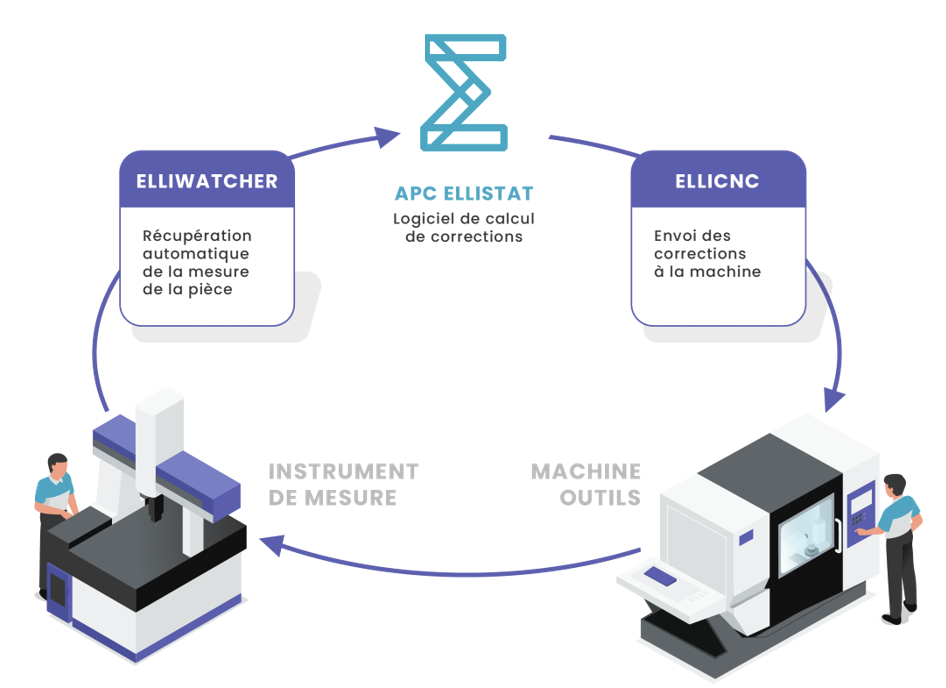

APC, Automated Process Control, APC is a closed-loop production control method that automatically corrects machine tools on the basis of measurement results. In contrast to traditional SPC, APC acts directly on the process, enabling a much higher level of quality, capability and robustness to be achieved.

Why deploy APC in production?

Implementing APC brings immediate gains in terms of industrial performance, product quality and process reliability.

The advantages of closed-loop production :

- elimination of input errors

- elimination of calculation errors

- common production strategy within the company

- improve process capability

- standard interpretation of measurement data

- traceability and history of corrective measures implemented

These benefits make APC a key lever for industries with stringent dimensional requirements (precision mechanics, aeronautics, automotive, watchmaking, medical, etc.).

Beyond the technical aspects, the deployment of APC radically redefines skills management on the shop floor. By automating complex calculations and corrector transfers, the experience barrier is eliminated: thanks to APC, any setter, whatever his or her level of seniority, becomes capable of piloting the process with expert precision. This standardization of skills considerably simplifies the recruitment and integration of new employees.

Far from replacing the human element, APC frees technicians from repetitive and stressful tasks, repositioning them on higher value-added missions, transforming the workshop into an agile, modern and sustainably efficient production environment.

Prerequisites for successful implementation of APC :

APC performance is based on a number of technical and methodological prerequisites:

- Reliable, repeatable measurement

- Measurement is the basis of APC. Without reliable measurement, any automatic correction becomes counter-productive. Measurement is the means of visualizing the state of production at a given moment. We recommend a metrological capability index Cmc > 4.

- An adapted programming strategy

- machine programs must be designed to integrate automatic correction logic in order to generate drifts.

- Correct machine capability

- A non-capable machine generates random variations that are impossible to correct. We recommend a machine capability Cp > 1.6.

- A comprehensive, consistent control plan

- The inspection plan must be strictly aligned with the specifications of the part drawing and the customer's requirements.

- Interconnection of measurement and production machines via ELLISTAT

- automatic processing of measurement data saves time

- reduced data entry errors

- reduced calculation errors

- Standardize your production range

- The manufacturing schedule is the guarantor of the manufacturing and inspection methodology. To optimize APC results, it must include :

- control plan corresponding to part drawing specifications

- manufacturing program

- selection of suitable measuring equipment

- standard, company-wide production strategy

- The manufacturing schedule is the guarantor of the manufacturing and inspection methodology. To optimize APC results, it must include :

Conclusion

The implementation of APC should not be seen as a simple software add-on, but as a genuine transformation of the workshop culture, a truly global industrial approach combining metrology, methods, production and digitalization. The ultimate goal is to deploy the solution on 100 % production islands. By making APC the absolute standard, the company is freeing itself from disparities in methods between teams and individuals.

This profound transformation provides a strategic guarantee: quality no longer depends on the sensitivity or experience of the operator. Control becomes an exact and constant science, ensuring «right first time» production, 24 hours a day.

In short, industrialized and standardized APC enables :

- Securing production Compliance is ensured by the system, regardless of turnover or training level.

- Transforming the workshop We're moving from a culture of «tuning by intuition» to data-driven management.

- Maintaining competitiveness : Maximum efficiency becomes the foundation of operational excellence.

APC thus becomes much more than a performance lever: it's the driving force behind a modern, agile industry capable of guaranteeing total quality in all circumstances.