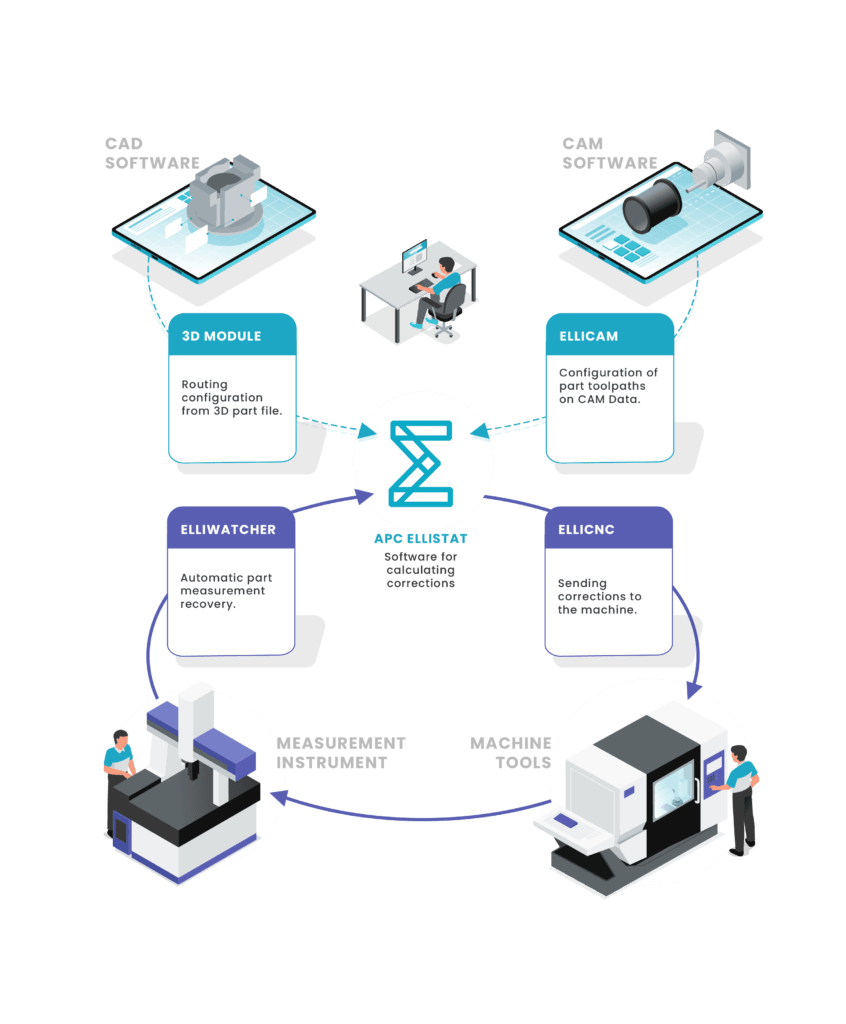

By integrating CAM data, APC software and its ELLICAM module automatically calculate the best fit. Set-up time is greatly reduced, and the first machined part conforms to the required tolerances.

Ellistat has just upgraded its software solution APC (Automated Process Control) with the ELLICAM module, which provides a major automation function thanks to the integration of computer-aided manufacturing (CAM) data for the Alphacam and soon TopSolid.

The APC is now capable of automatically calculating offsets, directly from the part's CAM file information, while also autonomously setting tooling parameters. ResultsAPC: set-up time reduced to 15 minutes per part, compared with 3 hours previously, as it was necessary to parameterize the APC by indicating which surfaces are machined by which tool.

The solution takes into account all the dimensions and offsets of a process to calculate the best fit. Machine Learning algorithms automatically calculate the offsets to be applied to the machine, based on the measurement of a single part. As a result, the first part machined for each production run complies with the required tolerances and is centered.

"With its ELLICAM module, the APC can be used for machining a single part as well as for launching a series". explains Camille FOREST, Marketing Manager. You only need to machine one part - instead of four or five as is often the case - to fine-tune all the settings. This is a major advantage for small production runs. " APC technology will profoundly change the way parts are machinedsays Davy PILLET, President of Ellistat. It's a revolution that will enable our customers and all industrial machinists to deploy APC on all machines, even for small production runs.

A constantly evolving solution

Maurice Pillet, a professor at Savoie Mont Blanc University, is behind the product: " I wanted to build data analysis software that was very easy to use. While advising my customers, I had the opportunity to correct machine tools. For this purpose, I developed a software package that gradually became APC? Innovation and customer feedback did the rest..

Ellistat is constantly developing its APC software. In 2022, automatic configuration from 3D CAD files in STEP format was introduced, considerably simplifying the configuration process. The following year, the integration of GPS part tolerancing enabled more complex parts to be corrected, and automatic connection to machine tools was introduced. In 2024, APC integrated measurement point clouds for machining complex shapes.

ELLICAM is currently being deployed with customers using Alphacam CAM software.

🖋️ Editor: Patrice DESMEDT

This ELLICAM project was funded by the French government as part of France 2030..

Funded by the European Union - Next Generation EU as part of the France Relance plan.