Since 2014, we've been working with machine shops, quality teams, process engineers and industrial managers on training and quality consulting, and one thing is clear.

The contexts change (machines, parts, sectors) but the same situations are repeated over and over again:

- Plants have never had so much data.

- Dashboards have multiplied.

- SPC systems have become more sophisticated.

- Alerts are everywhere.

And yet, in the field, we see the same drifts, the same manual adjustments, the same explanations after the fact.

- The problem is not a lack of competence.

- The problem isn't a lack of tools.

- The problem is that the operating model has not evolved.

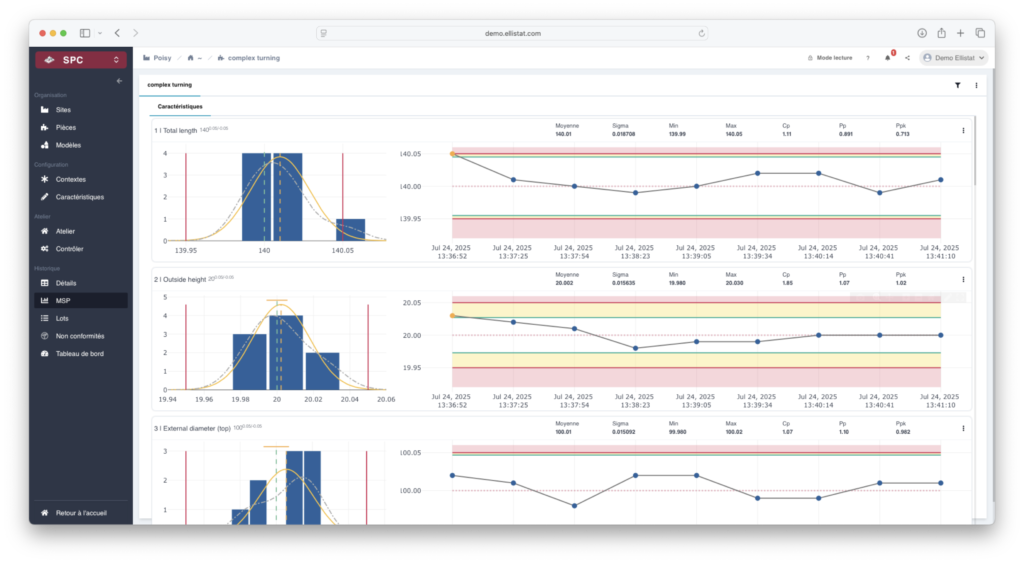

SPC: an industry that has become an expert... in reaction

The SPC has shaped the quality culture of modern industry. It has brought rigor, objectivity and a common language. For a long time, it was a major step forward.

But let's be honest.

In most workshops, the SPC translates into :

- operators monitoring cards, without even understanding them,

- engineers analyzing alarms,

- manually adjusted offsets,

- of variances explained after that they had an impact.

SPC has made factories very good at seeing problems. It never made them good at avoiding them.

It is a fundamentally reactive system:

- the process drifts,

- we can see it,

- we correct.

As long as complexity remains manageable, it works. But that world no longer exists.

The current reality: reaction no longer scales

Today, machining faces :

- more references,

- shorter series,

- ever tighter tolerances,

- compressed lead times,

- teams under constant pressure.

In this context, human reaction can no longer be at the heart of the control system. Not because people are incompetent. But because the system demands constant vigilance in an environment that has become too dynamic.

SPC says, «You're drifting.»

But it doesn't bring the process back on course.

Meanwhile, the rest of the world moved on.

Outside the factory, our standards have changed.

Today :

- we no longer sail without assistance,

- we no longer optimize without algorithms,

- we no longer correct everything manually.

Whether with navigation tools or driver assistance systems, we've moved on to something else: systems that continuously perceive, compare and correct.

Once accustomed to this permanent assistance, reverting to a purely reactive logic doesn't seem dangerous. It seems inefficient. And yet, this is exactly what the industry continues to do.

The most costly illusion: believing that SPC is control

This is one of the most common misunderstandings in the industry.

- Dashboards show reality.

- Alerts notify a deviation.

- SPC cards detect drift.

None of these tools stabilizes a process. The SPC systematically stops just before the action. It leaves the loop open.

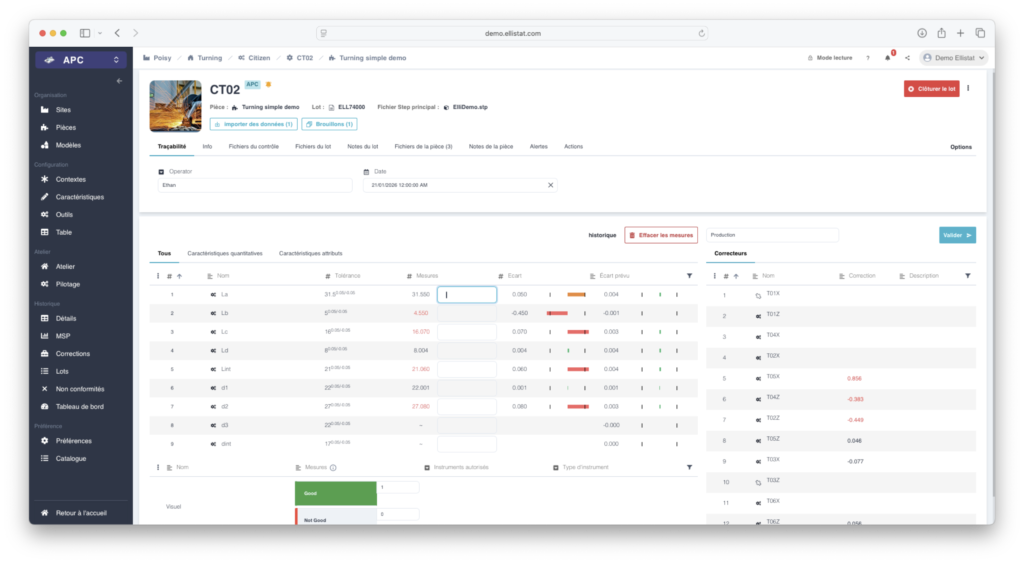

APC: finally closing the loop

L’APC (Automated Process Control) does not offer an «improved» version of SPC.

It proposes a paradigm shift.

Where SPC observes, APC acts.

Where SPC warns, APC corrects.

Where SPC depends on humans, APC reduces their cognitive load.

APC:

- exploits existing measures,

- models actual process behavior,

- anticipates drift trends,

- automatically adjusts machine parameters,

- keeps the process centered in time.

The operator no longer spends his time correcting. He supervises a stable system.

Let's be clear: in machining, the SPC is outdated

SPC is not useless. It is as a central control tool.

Keep believing we can manage:

- micrometric tolerances,

- inherently unstable processes,

- high speeds,

with a logic: measurement → warning → human → correction, is like driving while only looking at the dashboard.

It worked yesterday.

This no longer works.

Conclusion: machining needs its autopilot

After more than ten years of consulting in industry and machining, the conviction is unambiguous. The future of industrial performance:

- is not in more data,

- is not in more dashboards,

- is not in faster reactions.

He's in :

- fewer surprises,

- more stability,

- continuous, invisible corrections.

The real question is no longer, «Do we have an SPC in place?»

But: «What do we do automatically when the process starts to drift?»

In all other areas, the answer is already obvious.

Machining can no longer simply monitor. It must pilot. It must switch to APC.

And yes, it does mean one thing: SPC, as used in machining today, is dead.