Statistics

in 1 click

Use the power of statistics with Data Analysis to find out what's behind your production data

Free trial

Analyze your data

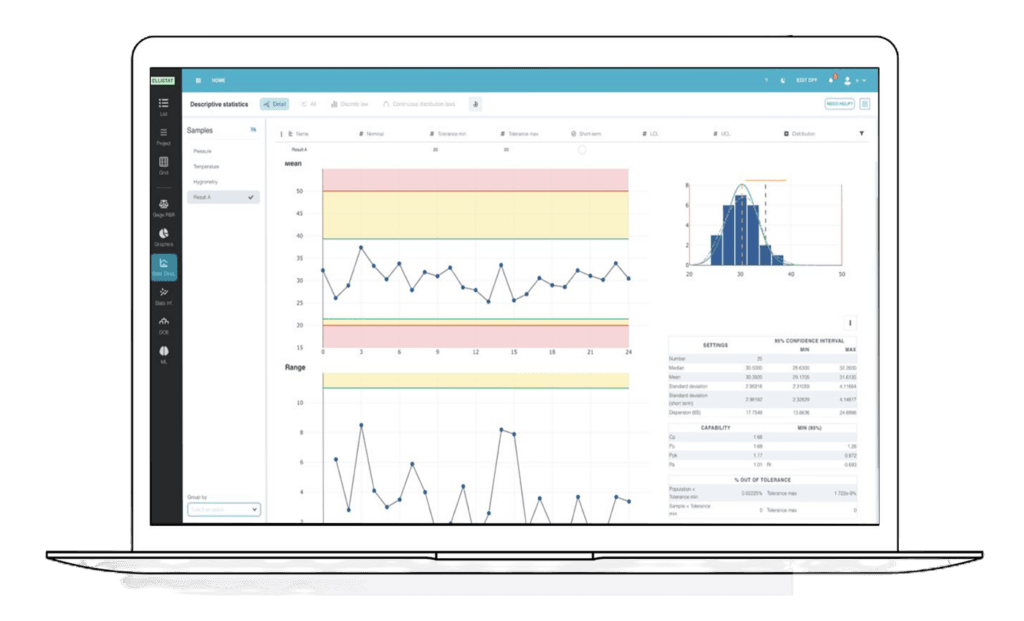

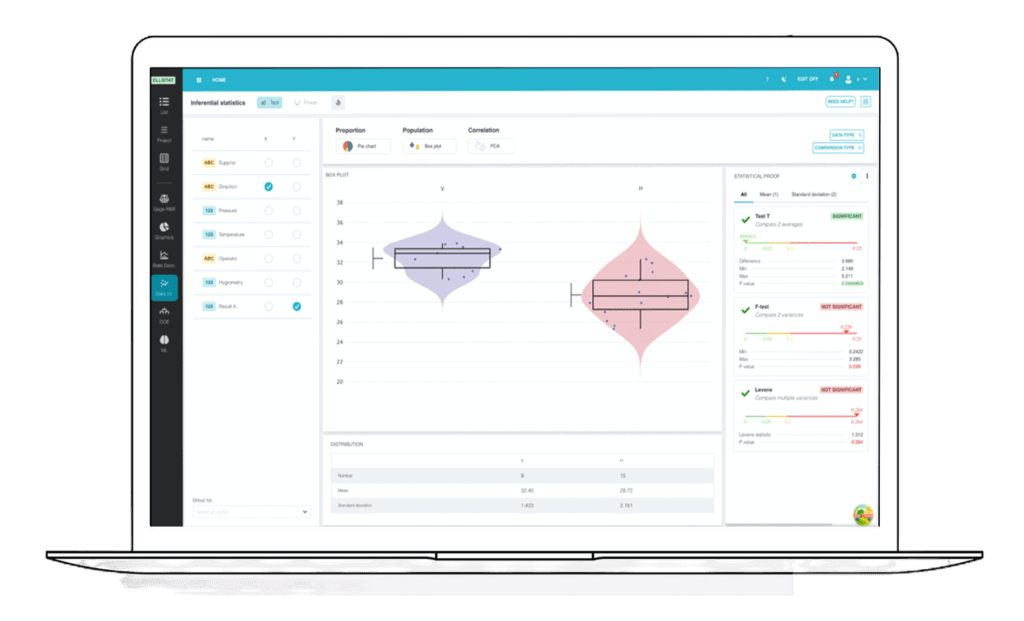

Improving business performance requires decisions based on facts and data. Analyzing data is no joking matter. Ellistat's Data Analysis software is designed to be intuitive and to guide you in the choice of statistical tests and the analysis of your data.

Whatever your level in statistics, Ellistat is for you!

View

your production data (capabilities, control charts, normality, etc.)

Build

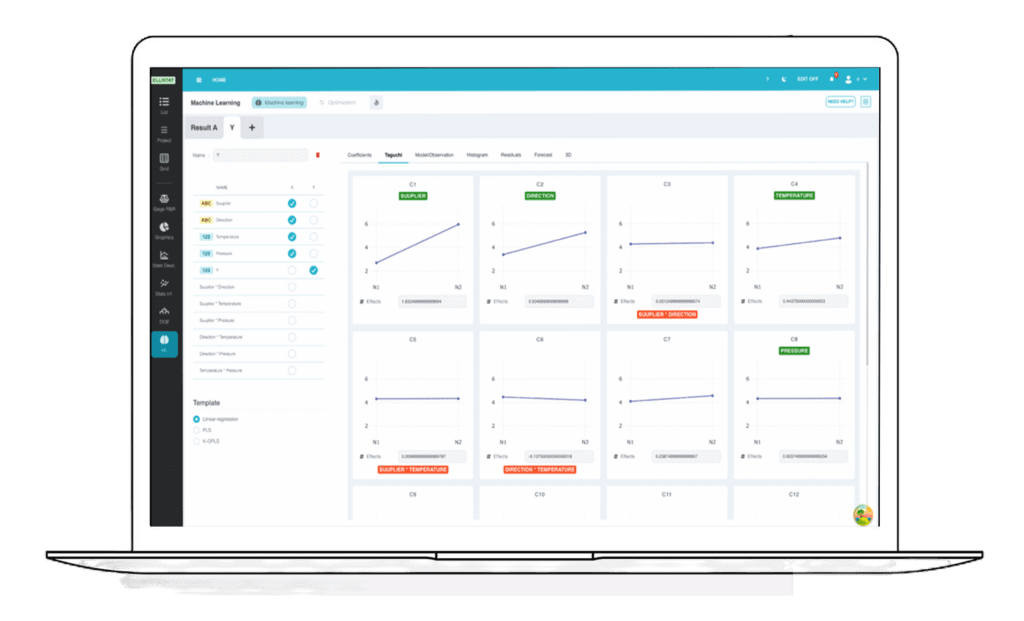

complete experimental designs, fractional designs, response surface designs...

Analyze your data

your test data with our machine learning tools

Your Feedback

Our Strengths

Ergonomic

Ellistat can be used by both inexperienced tuners and experienced engineers.

Complete

Find all your parametric and non-parametric statistical analyses in just a few clicks.

Floating licenses

Stop worrying about the number of installations and spread the statistical culture throughout your company.

1 license = 2 solutions

You have access to two versions of the software: Desktop and Online! Choose the one that suits you best.

Export to Office

Ellistat lets you export your data directly into Word, Excel or Powerpoint.

Didactics

Dialog boxes and results are organized to facilitate analysis and interpretation.

Try before you buy

- Demonstration15-day trial / 1 year for students0€

- SPC

- Statistical Analysis

- Experimental Design

- MSA

- Graphical Analysis

- Machine Learning

- StandardThe best in commitment-free data analysis95€

- SPC

- Statistical Analysis

- Experimental Design

- MSA

- Graphical Analysis

- Machine Learning

- Technical support

- Updates

- Unlimited number of users

- Tacit renewal subscription

- AnnualThe best in data analysis (2 months free)950€

- SPC

- Statistical Analysis

- Experimental Design

- MSA

- Graphical Analysis

- Machine Learning

- Technical support

- Updates

- Unlimited number of users

- Tacit renewal subscription

Read More

Data Analysis: powerful statistical analysis software

"With Data Analysis, you don't need to be a quality expert to analyze production data. Its simplicity ...

Process control: AI can work wonders

Artificial intelligence is transforming the industry, but deploying it requires method, reliable data and a clearly defined strategy, says ...

Minitab vs Ellistat?

Minitab vs Ellistat? Choosing a statistical analysis software package can sometimes prove difficult. Minitab is often associated with ...

What should I do if I get a bad Cpc?

What is Cpc: Cpc stands for Control Process Capability. It is used to identify a control process ...