Manage the traceability of your parts

With Ellistat's TRACE module, you have access to complete, centralized traceability for every batch. Track, record and consult the detailed history of each part, batch or product, at every stage of its life cycle: from manufacturing to shipping, via quality control.

The TRACE module enables you to retrieve all production data (operators, machines, dates, etc.) in real time, making it easier to respond to your quality audits.

Our Strengths

Customizable dashboards

Clear, intuitive visualization of production data.

Traceability

total

Automatic recording of all production steps.

Intuitive User Interface

Accessibility via various devices (PCs, tablets, smartphones, etc.)

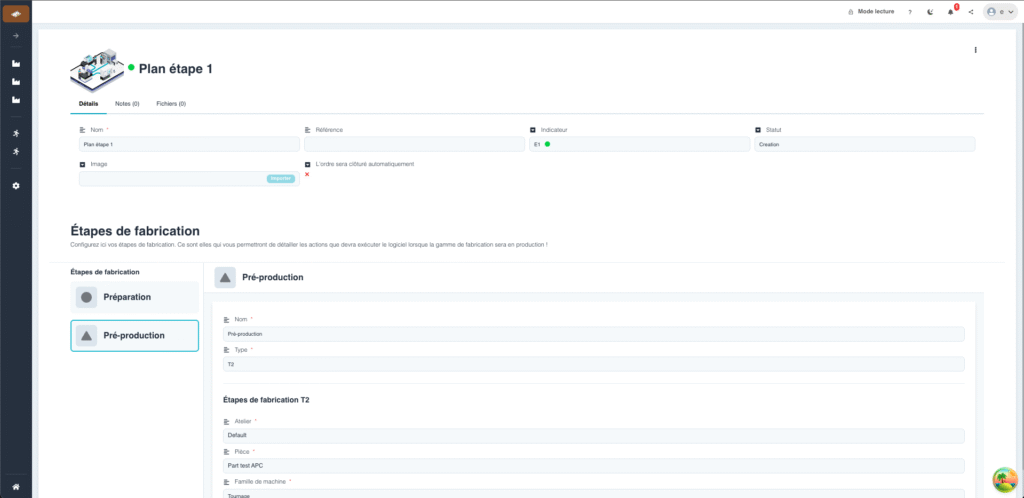

How does traceability software work?

The TRACE module enables you to track the progress of a production batch in real time, throughout all stages of the manufacturing process. It centralizes key measurement and traceability data in a single database, which can be consulted at any time.

This means that, in the event of an audit or non-compliance, the entire production cycle can be rapidly analyzed, thereby limiting the operational impact.

This type of solution also enables us to satisfy customer requirements and meet the most stringent regulatory standards. Particularly in the aeronautical, medical and automotive sectors.

Read MoreThis means that, in the event of an audit or non-compliance, the entire production cycle can be rapidly analyzed, thereby limiting the operational impact.

This type of solution also enables us to satisfy customer requirements and meet the most stringent regulatory standards. Particularly in the aeronautical, medical and automotive sectors.

Our key features

Registration of batch / series numbers

- Identify each product or component with precision, thanks to automatic registration of batch and serial numbers.

- Ensure complete traceability upwards and downwards.

Follow-up of operating ranges

- Keep track of every manufacturing step, operator involved and machine used.

- View the progress of a production order in real time.

Automatic reports

- Generate detailed, customizable traceability reports.

Combining production and control data

- Automatically link process data and non-conformities to the parts produced.

- Add quality control results for a complete picture.

Link to Ellistat quality suite modules

- Direct link with other Ellistat quality suite modules: APC, SPC, IQC and METRO.

Integration with Existing Systems

- Accessible On Premise / On Cloud, full web technology.

- API for integration with MES and ERP systems.

Your Feedback

Read More

Traceability: a key lever for quality and competitiveness

In an industrial environment subject to fierce competition and increasing regulatory pressure, product traceability is no longer ...

Traceability in medical production

A quality and compliance challenge In the medical industry, every part produced can have a direct impact on ...