In the 40 years we've been providing consulting and training services in the field of quality, we've come to a clear conclusion: for teams to take ownership of quality tools, operators and technicians need to speak the same language to create a COMMON CULTURE.

Quality objective

A quality culture is essential to any industrial company. It leads to better control of production techniques and improved processes. Speaking the same language is essential within a company. That's why Ellistat proposes to develop the skills of all employees within a company, and not just to train a few experts.

For this reason, Ellistat has specially designed over 70 training modules on Six Sigma, Lean and quality-related tools for industrial companies. For the first time, the training modules are available on an unlimited basis. Objective: train all employees to share a common culture of quality and operational excellence.

This e-learning training package is designed in the form of floating licenses. One license gives simultaneous, unlimited access to all Six Sigma, Lean and quality tools, i.e. over 70 training modules, specifically developed for e-learning training.

Davy Pillet, CEO of Ellistat: " In concrete terms, the Training Pack makes it very easy for a company to create personalized training paths for different functions. Some customers use it to train new employees as soon as they join the company, so that everyone has a basic set of skills and speaks the same language".

A flexible E-Learning training package

Employees follow one or more training courses, depending on their needs and objectives. Everyone is free to progress at their own pace, according to their own schedule and with complete autonomy.

"Unlike face-to-face training, explains Davy PilletFor example, it is no longer necessary to reach a minimum number of ten people to launch a training program. Nor is it necessary to decide to train only the two or three employees available, at full cost. With the Training Pack, we've also opted for profitability.

This innovative training offer, available at ultra-competitive rates, is designed for small teams and large groups alike. Its multilingual availability helps to homogenize the quality culture within companies operating internationally.

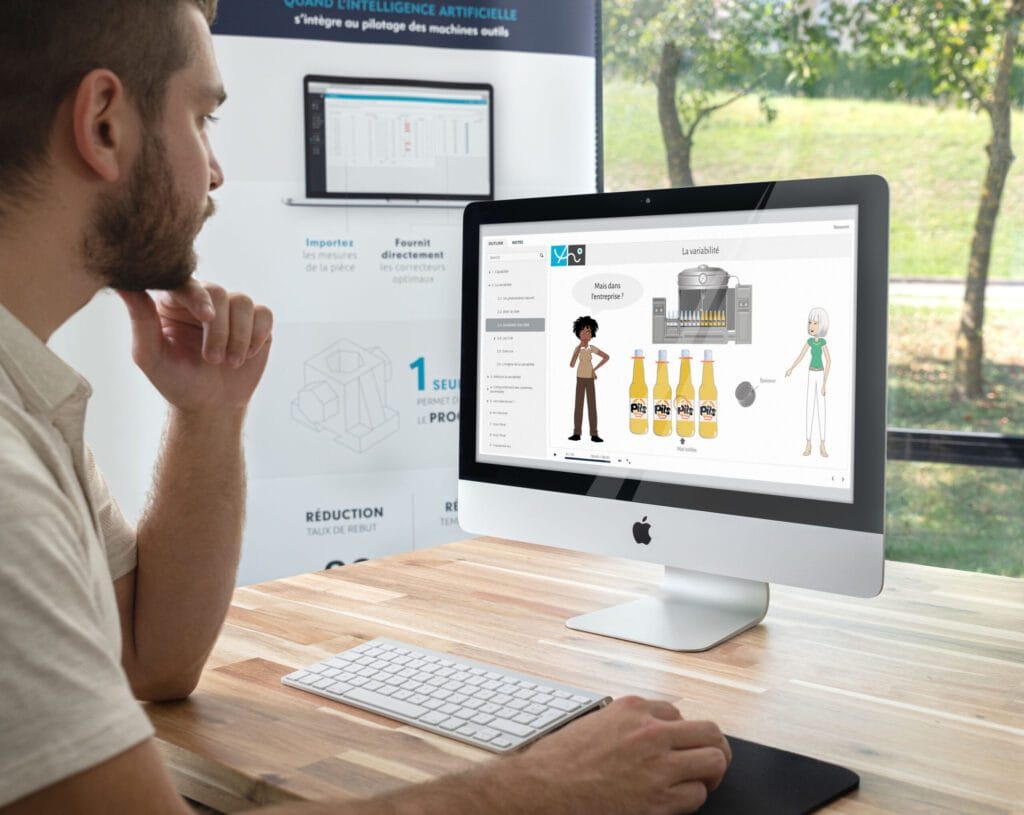

A fun E-Learning training package

When it comes to using the training modules, trainees appreciate the fun aspect and the immersive environment (a beer brewery), with voice-overs, exercises, animations and quizzes at each stage to check that they have understood what they have been taught.

From operators to engineers, our training courses are designed to be accessible to as many people as possible. Each module is animated and provides trainees with expert tools such as Ellistat data analysis software, as well as industrial process simulators for practical application. Thanks to these simulators, as they progress, trainees realize the relevance of their choices.

And Davy Pillet adds: " We have opted for an adapted teaching approach, focusing on the use of tools for immediate application. The simulators integrated into our e-learning training modules facilitate understanding, particularly in the case of an employee who is not necessarily at ease with quality tools, due to lack of practice."

Loïc Doubey, Quality Development & Control Methods Manager at one of our customers, comments: "We're very pleased with the quality of our products. An excellent e-learning training tool for a team of technicians and engineers in their integration cycle. The courses offered ensure a consistent level of competence in line with our customers' ever-changing needs. The solution is easy to use and highly flexible, notably via an annual license. "

Six Sigma training modules include capability, data analysis, experimental design, measurement system analysis (MSA), sampling control, process control (SPC), problem solving, machine learning, Green Belt Six Sigma and Black Belt Six Sigma. As for Lean tools: AIC, standardization, VSM, 5S, kaizen, Yamazumi, Kanban, SMED, Jidoka, TPM, AMDEC, POKA YOKE, Heijunka, DDMRP, Yellow Belt Lean, Green Belt Lean, Black Belt Lean.