APC (Automated Process Control) is a concept invented under the direction of Prof. Maurice Pillet by the research laboratory SYMME at Savoie Mont Blanc University. Automated Process Control is an evolution of SPC (Statistical Process Control) and consists in using IT resources to control a production process in order to achieve better quality results than with traditional SPC.

Today, APC is used on an industrial scale in a wide range of fields, and the benefits are clear to see. In the case of machine tools, Automated Process Control (APC) has reduced changeover times by a factor of 3 or 4, and cut scrap rates by a factor of 10. For some time now, Automated Process Control has been extended to other types of process, such as bending, injection, extrusion, etc., with equally impressive results.

Automated Process Control uses software available to the setter, which calculates the corrections to be made to the process based on the measurement of one or more products. Automated Process Control is based on two fundamental concepts:

- Control complex processes by mastering the simultaneous correction of dozens of correctors

- Correct drifts using a damping function

Managing complex processes

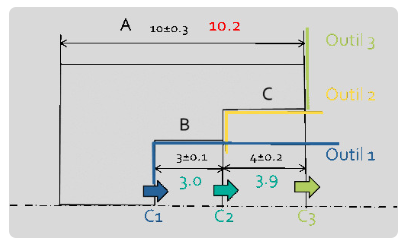

When monitoring complex processes that combine multiple, interdependent measurements, such as the machining of complex parts, machine set-up is often a difficult task. Take the following example:

We'd like to correct measurement A because, with a measurement of 10.2, it's out of tolerance. To correct it, you need to modify the stroke of tool C3, but doing so will modify dimension C, which is under control. Tool C2 must therefore also be corrected. Doing so will modify measurement B, etc.... The problem for the setter is how to correct all the tools C1, C2 and C3 to correct measurement A.

In this simple example, set-up may still seem trivial, but in reality, as the parts are more complex than the example above, the set-up process can take a considerable amount of time.

Automated Process Control (APC) automates the adjustment

To solve this setting difficulty, Automated Process Control software such as Ellistat's APC module automatically calculates the setting for each tool.

The set-up process is automated from a configuration file, which can be built either:

- Based on the unit impact of each tool

- From a file of three-dimensional part measurements

1. Based on the unit impact of each tool:

In this case, configuring Ellistat's APC module involves calculating the impact of modifying each corrector. The question to ask is simple: If I modify this corrector, which characteristics will be modified?

Once all the unit impacts have been calculated, which only needs to be done once during product industrialization, Ellistat's algorithms automatically calculate the corrections to be made for each setting. In the previous example, the result would be :

C1: -0.3 C2: -0.3 C3: -0.2

2. From the part's three-dimensional measurement file

In this case, setting up Ellistat's APC module is even simpler, since all you have to do is import a 3D measurement file and configure the offset types used by the machine. Ellistat's algorithms do the rest, automatically calculating the optimum offsets.

Whatever configuration is chosen, the setter no longer has to calculate the setting, as it is supplied automatically.

Implementing Automated Process Control offers multiple benefits compared to traditional process control:

- Enables you to track dozens or even hundreds of characteristics.

- Automatically calculates relationships between multiple correctors.

- Does not make calculation or sign errors.

- Suggests the most likely setting and standardizes setting methods between teams.

Correcting drift

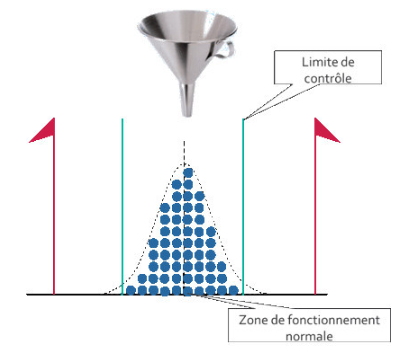

SPC limits

When controlling a process using SPC, control charts are used. Control is based on control limits, which symbolize normal process operation. When a measurement is within the control limits, there is nothing to be done: the process is under control. Conversely, when a measurement is outside the limits, this means that the process has drifted, and action must be taken, i.e. the process must be adjusted.

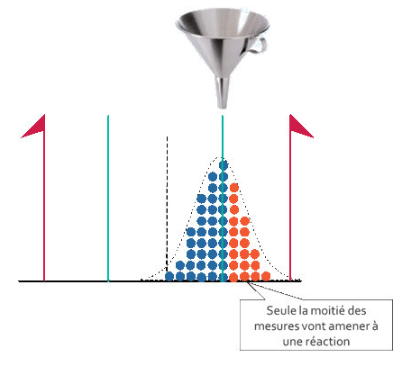

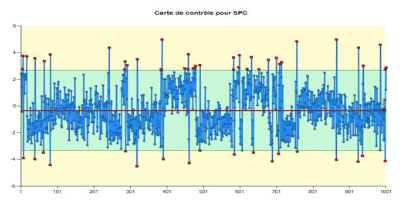

The problem with SPC is that it only allows you to react when the process has already drifted significantly. In the following example, the process has drifted, but only half of the measurements will lead to a result outside the control limits, and therefore to a reaction.

Automated Process Control (APC) damping functions

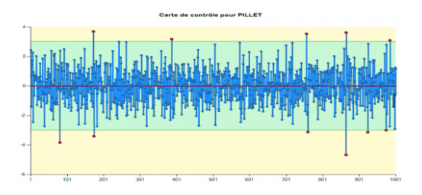

The use of a computerized tool to calculate the correction to be made makes it possible to be much more precise than a control limit which only contains the inside/outside information. In Automated Process Control, the process is corrected with each measurement to limit process drift.

The use of APC enables much better results to be obtained than with traditional SPC. The examples below show the use of the SPC and Ellistat's APC module on a process with drifts.

Process monitoring using traditional SPC :

Follow-up of the same process using Ellistat's APC software with Automated Process Control :

Conclusion

Automated Process Control enables production processes to be controlled automatically, enabling previously unattainable quality results to be achieved, and machine utilization rates to be significantly increased by minimizing downtime due to set-up.

Ellistat's APC module is the first software to fully implement the principles of Automated Process Control. It's easy to implement, and transforms your company's productivity and quality results.

Whether it's for monitoring a process with drifts, or for controlling a complex process, the algorithms offered by Automated Process Control simplify the work of the setter, and make it possible to imagine a whole new vision of process control.

The benefits of implementing Automated Process Control are manifold:

- Number of adjustment parts reduced to 1 : Automated Process Control minimizes the number of set-up parts. The scrap rate due to set-up parts (generally from 1 to 3%) is on average divided by 3.

- Set-up time reduced to a minimum : By automating set-up, you only need one part to set up a machine. This reduces set-up time to an absolute minimum, and increases machine uptime. For example, a gearbox housing that took half a day to set up before Automated Process Control was installed can now be set up in 30 minutes (production cycle time).

- Maximized quality indicators : With Automated Process Control, the number of out-of-tolerance parts can be considerably reduced compared to conventional control. Experience shows that the scrap rate due to out-of-tolerance parts is considerably reduced. Automated Process Control achieves Ppk quality indicators in excess of 1.33 for all characteristics.

- One-day setter training: Applying Automated Process Control is particularly simple. It takes just one day to train a setter in its use.