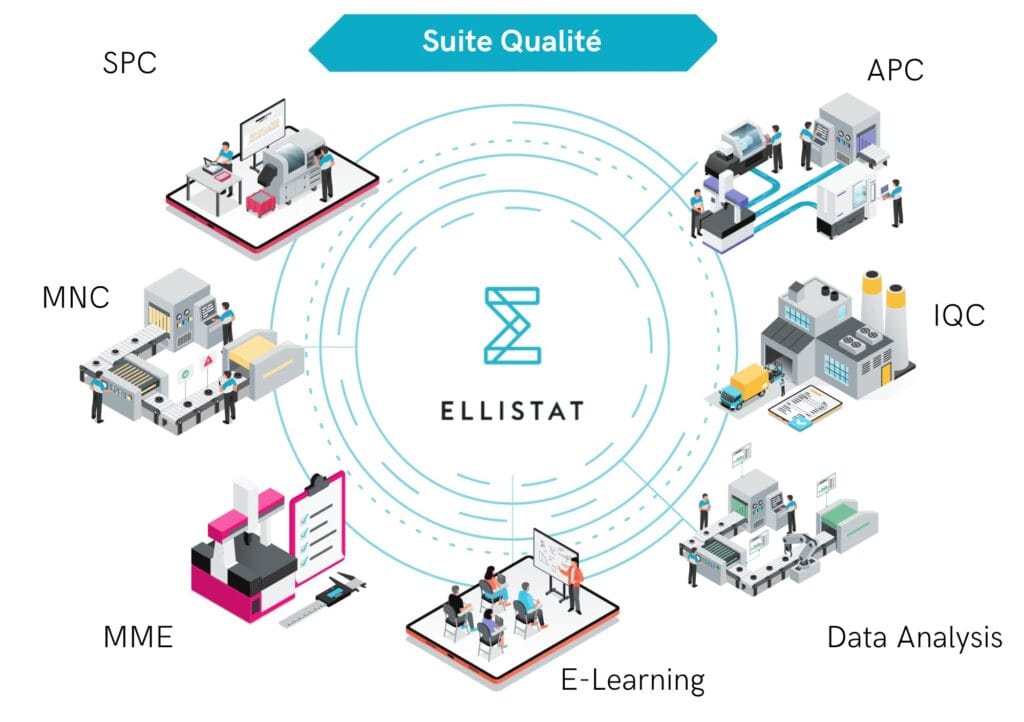

Ellistat, a software publisher best known for its APC software solution for automating machine-tool set-up, launches a new comprehensive software suite for production quality. This modular, innovative, intuitive and 100% Web-based Quality Control Software Suite is the fruit of strategic efforts and developments implemented right from the company's creation. Henceforth, Ellistat no longer positions itself solely as an expert in the machining sector, but more broadly as an expert in industrial quality. The Ellistat Quality Control Software Suite will be unveiled, in advance of the 1era at Global Industry Paris 2024.

From quality consulting to software development

Until now, the success of French company Ellistat has been based on its expertise in Lean and Six Sigma training and quality consulting. But also on its flagship APC (Automated Process Control) software. Numerous manufacturers and subcontractors in the medical, automotive, aerospace and watchmaking sectors have chosen this revolutionary, extremely easy-to-use technology. APC, which has won several awards at industry trade fairs, automates the process of setting up machine tools, ensuring quality compliance from the very first part machined.

Today, Ellistat is evolving into a complete software suite. Composed of various autonomous modules that communicate with each other. This is THE Quality Suite on the market, dedicated to industrial quality and created by quality experts. Development of this suite began over ten years ago. Initiated by Maurice Pillet*, father of Ellistat's founder, who is recognized as one of France's leading authorities on production quality. Over the course of his career, Maurice has published numerous works on Experience Plans, Process Control and Six Sigma. One of them, "Six Sigma - How to apply it has become the reference work in the field.

Davy Pillet, CEO of Ellistat: "We are delighted to present our Quality Suite to manufacturers. As part of their digitalization strategy, Ellistat aims to improve their operational efficiency, optimize their production processes, guarantee compliance with standards and regulations, reduce their production costs and finally improve the quality of their products.

With this Quality Suite, Ellistat aims to give a new lease of life to a long-established market. "We think there's still room for innovation," confides Davy Pillet.

A complete quality software suite focused on optimizing return on investment...

Now mature in its development, Ellistat offers a complete software suite for industrial quality. It includes all the standard functions traditionally offered:

- SPC (Statistical Process Control) This new feature enables you to monitor statistical process trends and control production in real time.

- IQC (Incoming Quality Control) :enables supplier samples to be checked. Thanks to its dynamization and progressive control functions, it is now possible to divide by 2 the number of controls carried out for the same incoming quality.

- METRO This is how we ensure the conformity of our control instruments. By tracking not only their calibrations, but also the associated R&R guarantees. The METRO module offers an efficient, automated approach to maintaining the accuracy of measuring instruments. Om guarantees product quality and compliance with standards and regulations.

- NON-CONFORMITIES The NON-CONFORMITIES module enables efficient detection, tracking and resolution of non-conformance incidents. The NON-CONFORMITIES module improves responsiveness, traceability, efficiency and prevention of quality-related problems. It thus contributes to enhanced customer satisfaction and regulatory compliance.

...with new features

In addition to offering an innovative user and technical approach to "standard" functionalities, Ellistat also offers new additional modules:

- DATA ANALYSISThe Data Analysis module can be used to calculate capabilities, design experiments, etc., as well as to statistically analyze data from the SPC and IQC modules. The Data Analysis module stands out for its rich functionality. Its machine learning algorithms can be used to understand the origin of machine drifts, or to statistically differentiate between suppliers.

- E-LEARNINGLean and Quality: 70 training modules to train all employees in Lean and Quality tools and upgrade skills throughout the company.

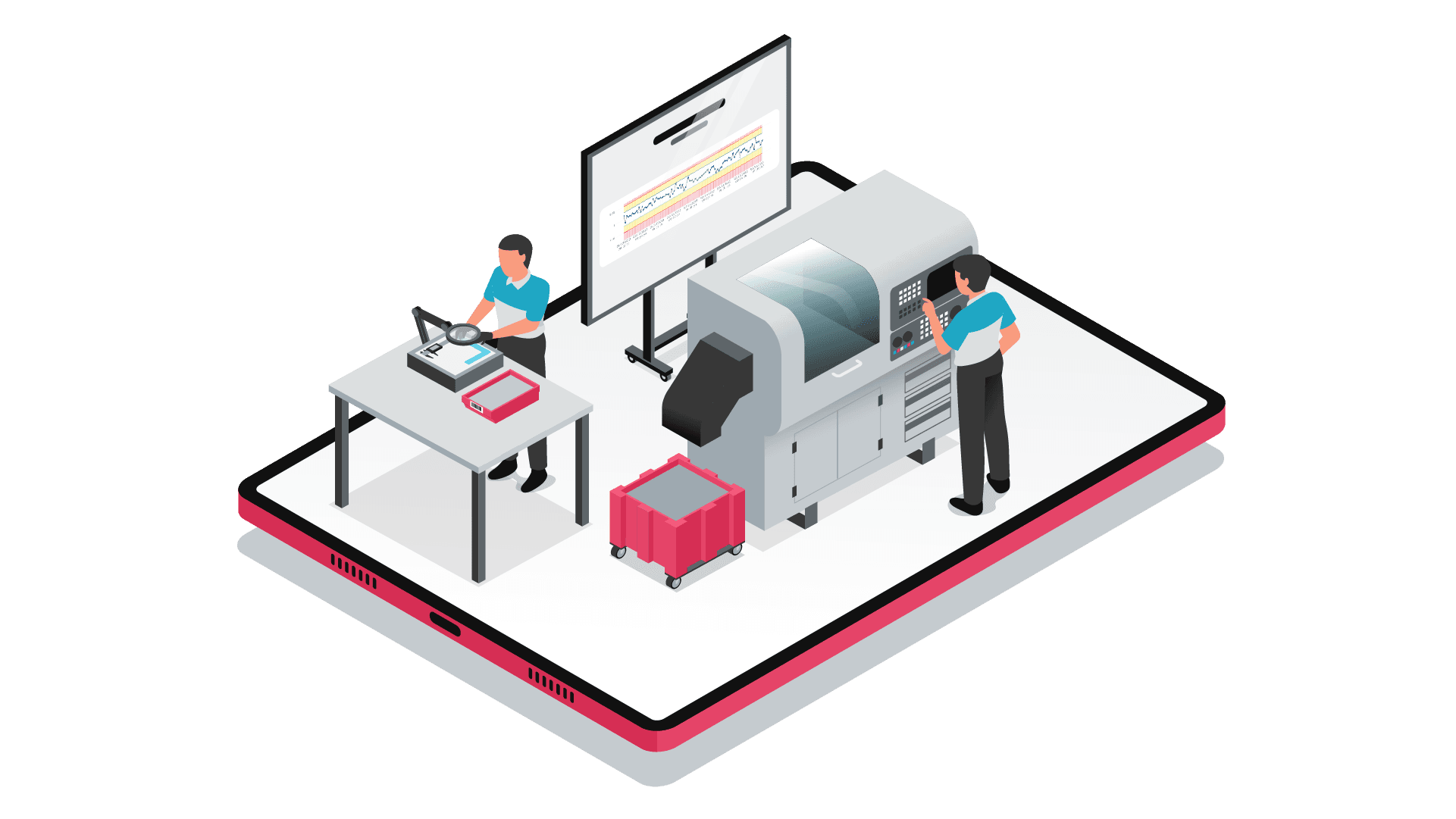

- APC (Automated Process Control)Dedicated to the machining market, this module automates the process of setting up machine tools, ensuring quality conformity right from the first machined part.

Davy Pillet comments: " At the cutting edge of innovation, the development of the Ellistat Quality Software Suite has focused on maximizing return on investment. The idea, for example, is to see to what extent it is possible to reduce the number of controls, while maintaining the same quality. Or, with the SPC module linked to the Data Analysis module, to obtain data but above all to be able to use it to find out where the problem comes from, and then be able to make the right decisions."

Ellistat's Quality Control Software Suite is easy to use and implement

The solution is based on a native "full web" architecture. The most obvious advantage of this architecture is its nomadic nature. Users can connect to the software from any terminal connected to the Internet, via a simple browser. The second advantage is the fluidity of navigation for users and the speed of response of the platform. It is supplied in Saas mode (software hosted by the publisher) or On-Premise mode (software installed directly on the customer's network).

To implement the solution, Ellistat offers its customers a support package. (> Find out more : Pilot Project, SPC support, IQC support).

First of all, we carry out a diagnostic on the customer's site, to determine the best method for deploying the solution. We then move on to the preparation phase, which enables us to be precise during implementation. Finally, we provide 3 or 4 days of on-site training, depending on the number of modules.

Davy Pillet: "We're proud of what we've achieved, and of being able to offer manufacturers a complete software suite for production quality. Ellistat represents the most powerful solution on the market, with full Web technology applied to all modules, for extremely simple, user-friendly and super-ergonomic operation.

* Statistician trained at the Ecole Normale Supérieure de Cachan, Research Director at the SYMME Laboratory and inventor of the concepts of inertial tolerancing and inertial process control.