A design of experiments XN is an experimental structure in which each factor can take on a number of discrete values or levels. These levels represent the different conditions or states in which each factor can be tested. Unlike 2-level Taguchi designs, the term XN stands for "N-level", meaning that each factor can have a variable number of levels, which can be different for each factor. This technique is commonly applied when the Y response is known to vary non-linearly as a function of one or more X factors.

Industrial Problem Statement - Design of experiments XN

Process description

ELLITEXTILE produces technical fabrics used in the manufacture of outdoor clothing, notably jackets and pants. The manufacturing process involves chemical treatment of the fabrics to make them hydrophobic and stain-resistant. This treatment is carried out by immersing the fabrics in a chemical solution, followed by a thermal drying phase.

Issues

The quality control department has observed that some fabric batches do not have the expected water and stain resistance. This leads to customer returns and a negative impact on the company's reputation. To remedy this situation, PolyTex wishes to optimize the treatment process to ensure that all fabrics achieve the required level of performance.

Identified factors

After a series of analyses and discussions with the technical team, two main factors were identified as having a significant influence on fabric quality:

- Chemical Solution Concentration (Factor 1)

- Levels:

- Level 1: 5%

- Level 2: 10%

- Level 3: 15%

- Level 4: 20%

- Levels:

- Drying temperature (Factor 2)

- Levels:

- Level 1: 100°C

- Level 2: 120°C

- Level 3: 140°C

- Levels:

ObjectiveOptimize the hydrophobic properties and stain resistance of fabric by adjusting chemical and thermal treatment parameters, in order to reduce production defects and improve customer satisfaction. In this case, the answer to be optimized is water resistance measured by the contact angle between water and fabric. An angle greater than 150° is considered optimum.

Test matrix generation with Ellistat - Design of experiments XN

- Click on the "DOE"then click on the map "Xn".

- In the zone 1You can set the tab name, choose the plan table, and add the maximum number of levels. 📝: Set tab name "ELLITEXTILE "This will create a new tab in the grid page.

- In zone 2, we can put the number of factors, name them and then put the values of the different levels. 📝: Put 2 factors :

- Concentration (min=5, N1=10, N2=15, max=20)

- Drying temperature (min=100;N1=120;max=140)

- In zone 3, you'll find a preview of the test matrix, which you can create in the create tab in zone 1. You can also create a D-optimal design, which is a type of experimental design that aims to maximize the statistical efficiency of an experiment while minimizing the number of trials required. 📝: Click on "Create DOE".

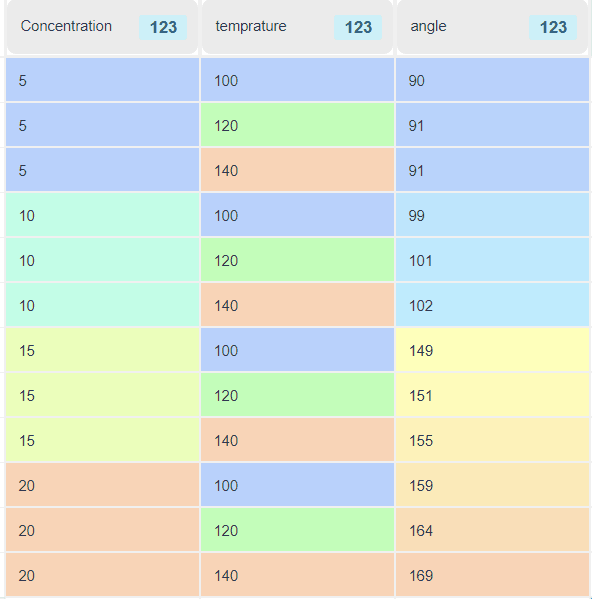

- In the "ELLITEXTILE" grid "The test matrix with 12 tests.

- In the next column, you can manually add the angle results as shown in the following figure: DOE XN