The response surface designs are methods used in statistics to model and optimize processes in which several independent variables influence one or more measurable responses. This technique is commonly applied when the response Y is known to vary in a non-linear (quadratic) way as a function of one or more factors X.

Ellistat Data Analysis offers a variety of response surface designs. The table below summarizes the list of available designs:

Example of a response surface design

In the company ElliWelding Welding is a crucial operation for assembling metal components. The main objective is to produce high-quality welds that guarantee the strength and durability of the assembly. Weld quality is influenced by several parameters, such as welding current, welding speed and arc voltage.

Optimization objective

Maximize tensile strength of the welding process, while minimizing internal defects such as porosity or cracks.

Factors considered

- Welding current (I):** Measured in amperes (A).

- Welding speed (S):** Measured in millimeters per second (mm/s).

- Arc voltage (U):** Measured in volts (V).

Measured Response

- Tensile strength (y):** Measured in megapascals (MPa).

Central Composite Design (CCD)

To analyze and optimize this process, a composite response surface design (CCD) is used, which includes factorial, axial and central points to estimate linear, quadratic and factor interaction effects.

CCD Plan configuration

- Factors I, S, U.

- Types of Points :

- Factorial points To estimate the main effects.

- Axial points To explore quadratic effects.

- Central Point To evaluate repeatability and variance.

Generating the test matrix with Ellistat

- Click on the "DOE"Then click on the "response surface**"** design.

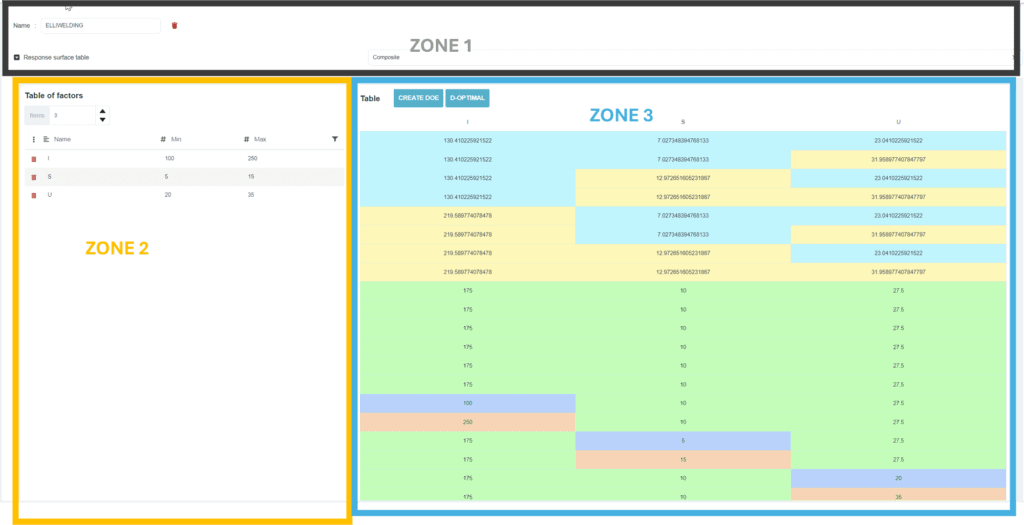

- In the zone 1You can set the tab name and choose the experimental design array. 📝: Set tab name "ElliWelding"Then select the "composite" design.

- In zone 2, we can put the number of factors, name them and then put the value of the min and max 📝: Add 3 factors :

- I (min=100 A; max=250A)

- S (min=5mm/s,max=15mm/s)

- U (min=20V;max=35V)...

- In zone 3, you'll find a preview of the test matrix, which will be generated in the tab created in zone 1. You can also create a D-optimal design, which is a type of experimental design that aims to maximize the statistical efficiency of an experiment while minimizing the number of trials required. 📝: Click on "Create DOE".

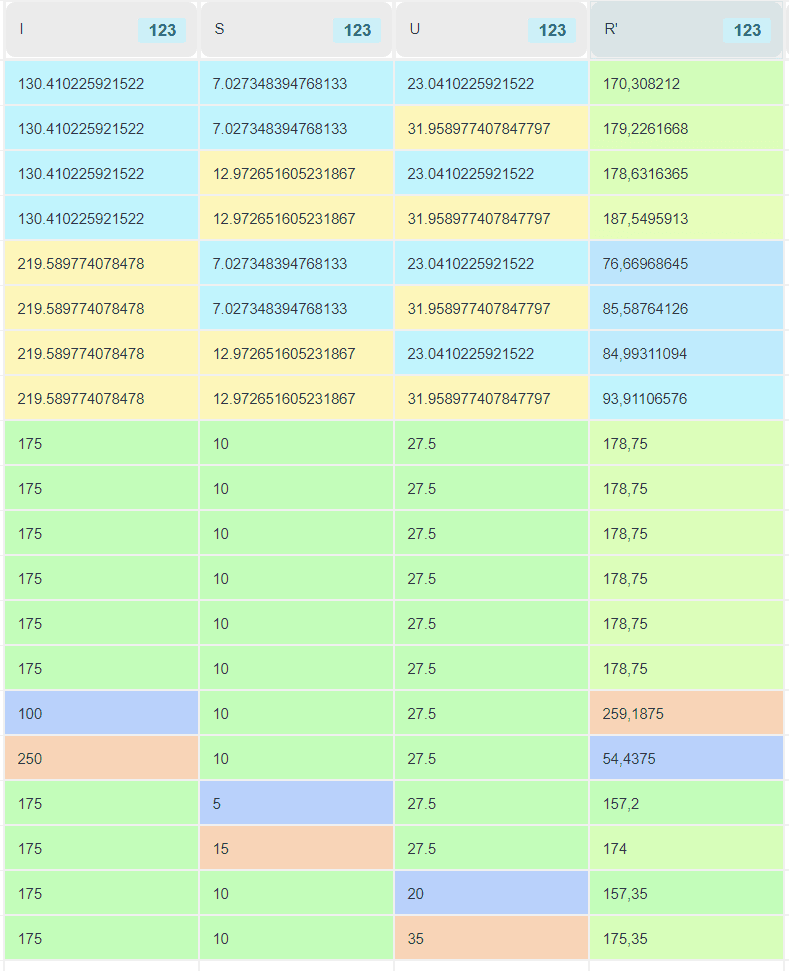

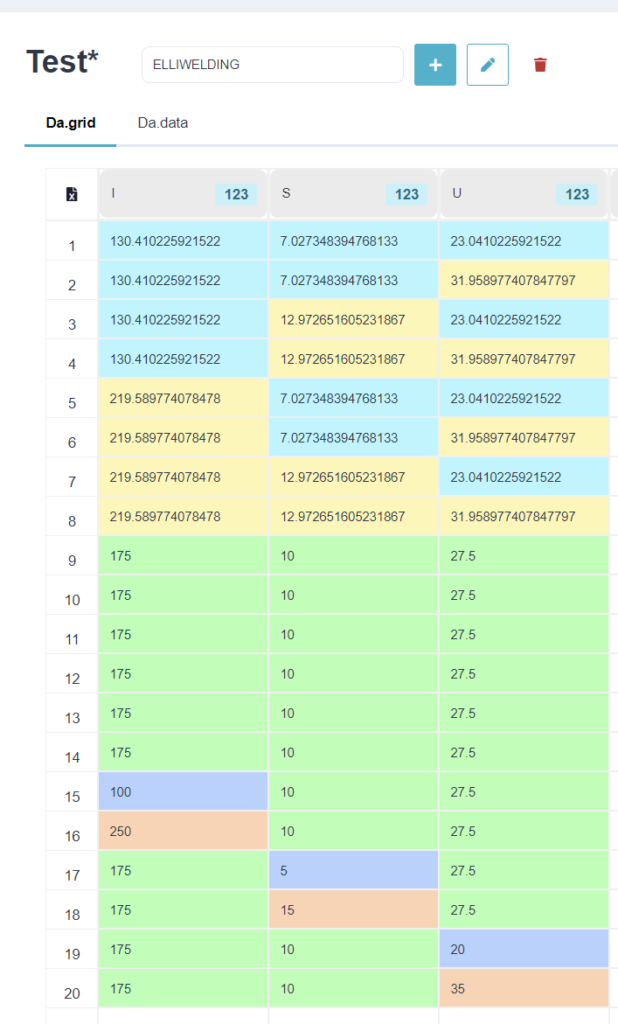

- In ElliWelding" gridThis is the array of experiment trial runs. This array contains the minimum and maximum level values entered during design creation, as well as other intermediate values used for factorial, central and axial trial runs.

- In the next column you can manually add the trial run results as shown in the following figure: DOE Response surface